Pipe fitting is a deceptively complex art. After all, a system of pipes can’t function properly unless each piece is fitted correctly, with the proper selections. It can be hard to pick those out of the many offerings that are out there, though, which is why it’s such a complicated job at the end of the day.

Considering what pipe systems are used for, this is really no surprise. From moving chemicals to powering a ton of different manufacturing processes, they’ve got a big job to do. Naturally, that means that each part of the system has to be in tip-top shape, and the fittings have to be able to hold them together without making them all too stiff.

This goes for vacuum chambers and fittings too, of course. You can read a bit more about them here, https://instrumentationtools.com/flanged-pipe-fittings/, but we’ll be going into details in this article as well. There’s so much to learn, it’s hard to fit it all in one place!

What are Vacuum Environments?

In order to create the optimal vacuum environment, it’s pretty important to know what they are first. When it comes to industrial uses, typically they’re in vacuum pumps. These are rather important in ensuring the quality of whatever is being manufactured since they help keep contaminants out.

Vacuum pumps are able to create either low pressure or partial seals. Inside the chamber, which in this case is the pipe itself, it creates a space where the pressure is not as high as it is outside of the chamber. By pushing any of the air or other gas molecules out of that portion of the pipe system, it achieves this effect.

This is different than the sort that you might see out in space so don’t confuse them. That’s known as an “absolute” vacuum, which is not really what we’re going for in manufacturing. Instead, the goals are much more grounded. They’re commonly seen in household items like the famous vacuum cleaner or incandescent lightbulbs. Read through to learn more.

Why Fittings Matter

One of the key parts about creating a chamber like the ones described above is that there can’t be any leaks or holes anywhere along the pipes. After all, if that were to happen, the vacuum seal wouldn’t really work. Extra air or gas particles could end up in the chamber, and not all of it would be able to be expelled.

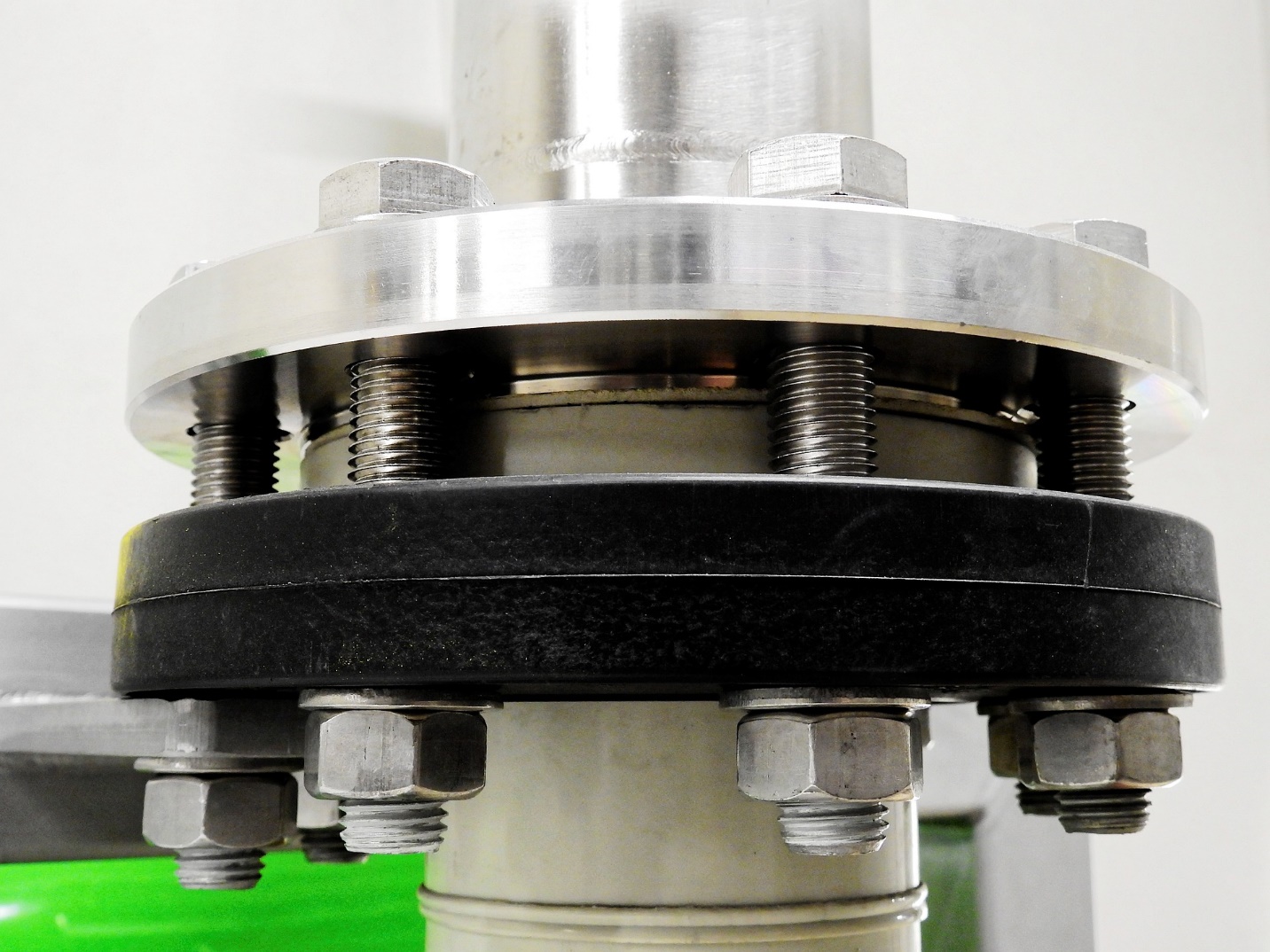

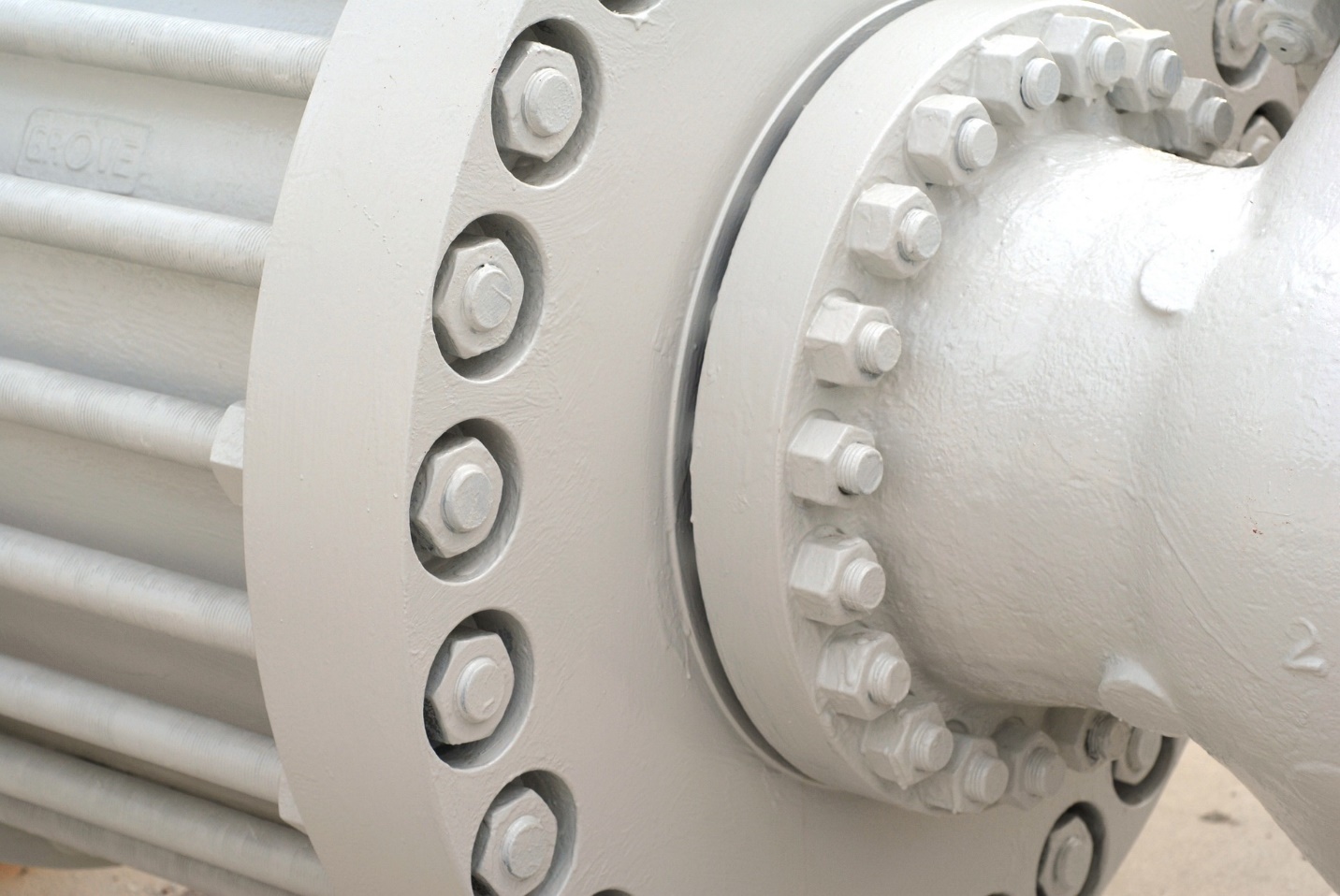

That’s where flanges and fittings come into play. Their purpose is to connect different pieces in a system, so they’ve got a pretty big role to serve. Ideally, they’ll be both sturdy and durable while also being easy to remove to allow us to go in and take the system apart later. Since cleaning and maintenance does need to happen, it doesn’t really serve our purposes if the flanges are stuck in place forever.

That’s why finding vacuum fittings that fit correctly is such an important part of creating the seal and/or pump in the first place. Because of that need for flexibility as well as strength, sometimes it can be hard to find a seller that has the components that we’re looking for. Thankfully, there are plenty out there online that carry all sorts of different parts.

What can we be on the lookout for, there? Well, some marks of quality include listing what the materials are or including a wide range of different flanges and fittings. Some examples might be aluminum, brass, high pressure steel, or cast iron, just to name a few. Really, the important part is that the ones that you select will work for the vacuum seal you need them for.

So, consider what will be travelling through those chambers. If there are any corrosive chemicals, both the pipes themselves and the flanges will need to withstand them and not get damaged. That can certainly factor into the materials that you want them to be made out of.

Additionally, think about the shape of the system involved. Most retailers have several different connector options available that can suit even the strangest of shapes, so you won’t have to worry too much about it. Just try to make sure that they’ll be able to twist correctly!